Machine Control Receivers

Filters

-

Original price $699.95 - Original price $699.95Original price List Price: .$699.95$699.95 - $699.95Current price $699.95| . /

AdirPro MC-10 Machine Control Laser Receiver

AdirProNo reviews- Signal: 360-degree Reception

- Operating Time: 40 hours

- LED display for easy visibility in all light conditions

- Built with aluminum housing and shock-mounted electronics

- Includes heavy-duty carrying case

- Adapts to any earth-moving machine

Original price $699.95 - Original price $699.95Original price List Price: .$699.95$699.95 - $699.95Current price $699.95| . / -

Original price $945.00 - Original price $945.00Original price List Price: .$945.00$945.00 - $945.00Current price $945.00| . /

LMR-240 Machine Control Receiver

Leica1 review- Quick Release Magnet Mount

- Operating radius: 650 ft

- Accuracy: fine 1/4"; coarse 1.2"

- Capture window: 5-3/4"

- Stores last signal received

- LED indicators

- IP67 protection class

- 240° detection with any rotating laser

Original price $945.00 - Original price $945.00Original price List Price: .$945.00$945.00 - $945.00Current price $945.00| . / -

Original price $1,971.00 - Original price $1,971.00Original price List Price: .$1,971.00$1,971.00 - $1,971.00Current price $1,971.00| . /

MR360RA 360 Machine Control Receiver w/ Remote Display

GeomaxNo reviews- All-around 360° detection

- Accurate readings, with up to 9 display channels

- Easy-to-use remote display

- Sturdy build with an IP67 rating

- Quick mounting via magnets

Original price $1,971.00 - Original price $1,971.00Original price List Price: .$1,971.00$1,971.00 - $1,971.00Current price $1,971.00| . / -

Original price $1,051.66 - Original price $1,051.66Original price List Price: .$1,051.66$1,051.66 - $1,051.66Current price $1,051.66| . /

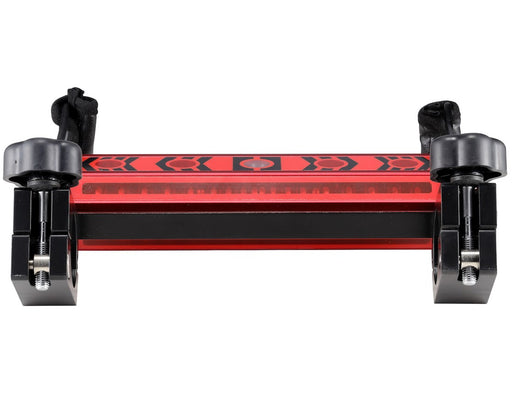

Machine Mountable 360 Degree Detector with Clamp and Magnet

Johnson LevelNo reviews- Optional Johnson Level 40-6792 Remote Display (sold separately)

- 360-degree reception angle

- Magnet and clamp mount

- LED indicators

- NiMH rechargeable battery pack

- Large 10" receiving window

- Durable housing material

- Battery life up to 40 hours

Original price $1,051.66 - Original price $1,051.66Original price List Price: .$1,051.66$1,051.66 - $1,051.66Current price $1,051.66| . / -

Original price $1,695.00 - Original price $1,695.00Original price List Price: $1,695.00$1,695.00$1,695.00 - $1,695.00Current price $1,695.00| . /

LMR-360R Machine Control Receiver

LeicaNo reviews- Magnet and clamp mount

- 360-degree reception angle

- Built-in vertical indicator

- Two detection accuracies

- LED indicators

- 9.75-inch capture window

- Battery life of 30 hours

- IP67 dustproof & water immersible

Original price $1,695.00 - Original price $1,695.00Original price List Price: $1,695.00$1,695.00$1,695.00 - $1,695.00Current price $1,695.00| . / -

Original price $1,530.00 - Original price $1,530.00Original price List Price: $1,530.00$2,030.00$2,030.00 - $2,030.00Current price $2,030.00| . /

MC200 DepthMaster Digging Machine Control Receiver

LeicaNo reviewsOriginal price $1,530.00 - Original price $1,530.00Original price List Price: $1,530.00$2,030.00$2,030.00 - $2,030.00Current price $2,030.00| . /

MACHINE CONTROL RECEIVERS & BUYER’S GUIDE

Machine Control Receivers are time-saving tools that give machine operators accurate grade information without stepping out of the cab. With a properly set up Machine Control Receiver, construction projects can be finished faster with higher precision, ultimately boosting your bottom line. Tiger Supplies provides a wide range of Machine Control Receivers at low prices, ranging from starter to higher-end models with advanced features like a 360-degree detection window, angle compensation, and plumb indicator.

Machine Control Receivers are time-saving tools that give machine operators accurate grade information without stepping out of the cab. With a properly set up Machine Control Receiver, construction projects can be finished faster with higher precision, ultimately boosting your bottom line. Tiger Supplies provides a wide range of Machine Control Receivers at low prices, ranging from starter to higher-end models with advanced features like a 360-degree detection window, angle compensation, and plumb indicator.

OUR BEST-SELLER

The Topcon LS-B200 Machine Control Laser Receiver is a great tool for increasing accuracy, productivity, and grading in excavation work. It has a 360-degree reception window for easy detection of red lasers and a built-in mechanical clamp for mounting on earthmovers. The Topcon LS-B200 is also one of the few Machine Control Laser Receivers with a tilt indicator which allows the operator to check grade even when the bucket is tilted. If you’re looking for a top-of-the-line Machine Control Laser Detector that can save you time and money, the Topcon LS-B200 is the top choice.

MACHINE CONTROL LASER DETECTOR BUYER’S GUIDE

Choosing the right Machine Control Laser Detector can be tricky with all the choices in the market. The key is knowing how you will use it and the features that will make your operators’ lives a lot easier.

How to Use Machine Control Laser Receivers

Machine Control Laser Receivers are used in the field in two ways: through a laser display system and an automatic grade control system.

Laser-Based Display System

In a laser-based display system, the Machine Control Receiver is mounted on a mast or on the machine’s bucket/stick and provides constant grading guidance as it detects the rotary laser. This enables you to excavate or trench with accuracy without needing to step out of the cab or have another guy check the grade for you.

Automatic Grade Control System

The automatic hydraulic control system is a next-level system wherein the Machine Control Receiver keeps you on grade and automatically controls the machine’s blade for grade correction.

This system has 3 parts: the laser level, machine control receiver, and a control box. The machine control receiver, once it detects the laser, relays the grade signal to the control box installed inside the machine’s cab. This control box is connected to the machine’s hydraulic system, enabling it to automatically adjust the blade’s height and angle. Since this system can speed up jobs and reduce stakeout requirements, it can lower costs, lessen reworks, and reduce idle machine time.

|

Top Machine Control Laser Receiver Brands Ensure quality and years of reliable performance with the following leading manufacturers of Machine Control Laser Detectors: Topcon | Spectra-Precision | Adir-Pro | Leica | Johnson-Level | Geomax | Seco |

Features of Machine Control Laser Detectors

To avoid over or underspending, it’s important to know the features you need to look for in a Machine Control Receiver based on your needs.

1. Reception / Detection Area - The reception or detection area pertains to the size or degree of the area in which the receiver can detect lasers. Affordable models like the Spectra Precision CR700 Combined Machine Control Receiver have a 200-degree reception window while higher-end models like the Spectra Precision LR60 Laser Machine Control Receiver have a 360-degree reception window. A larger reception window for Machine Control Laser Receivers saves time since it allows for easier laser detection.

2. Accuracy Settings - Machine Control Laser Receivers often have a number of accuracy modes or levels to suit different applications. Most receivers have 4 accuracy settings: fine, medium, coarse, and ultra-fine. The coarse option should be sufficient for rough grading, but you might want ultra-fine to fine accuracy for final grading. Make sure to look at a Machine Control Receiver's accuracy modes to see if it has the level you require for the applications you will be doing.

3. Mounting Options - Machine Control Receivers usually come with a built-in clamp or magnetic mounts for easy mounting on any earthmoving machines. Receivers can also be attached to masts that are placed at the front of the machine.

4. Angle Compensator - Angle compensation is an advanced feature that allows operators to check grade even when the bucket is tilted. It works much like the Topcon LS-B200’s tilt indicator. Medium to large construction projects will most benefit from this time-saving feature.

5. Plumb Indicator - A plumb or vertical indicator tracks the machine's stick's angle and indicates whether it is plumb, overextended, or underextended. This characteristic is essential to prevent over or undercutting. This feature boosts the efficiency of earthmoving crews in medium to large projects.

Other features you need to pay attention to are the power source, battery life, and how well it stands against the elements and rough use.

Picking the right Machine Control Laser Receiver will help you boost your efficiency and get the most out of your investment. If you need more help with selecting the right receiver, give us a call and our team of experts will be happy to help!